Cement Industry Bearing Application

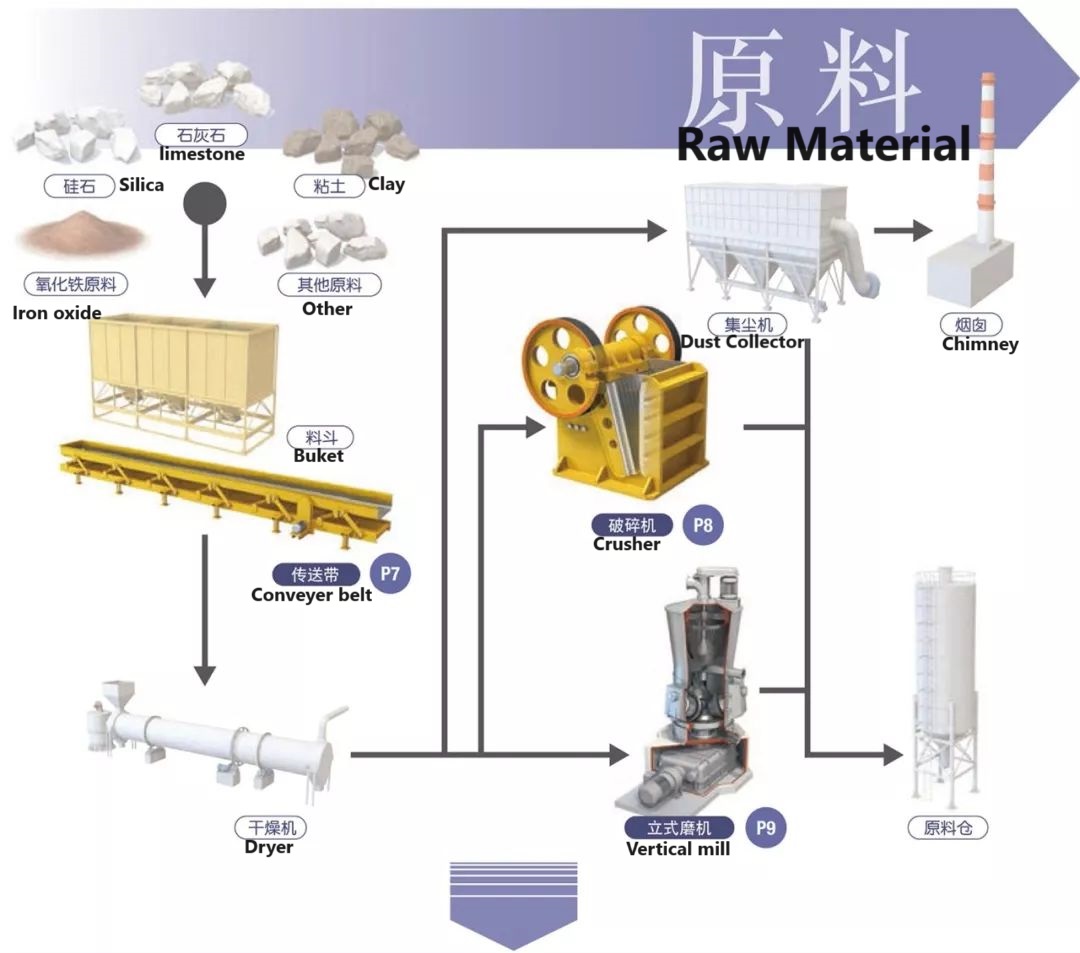

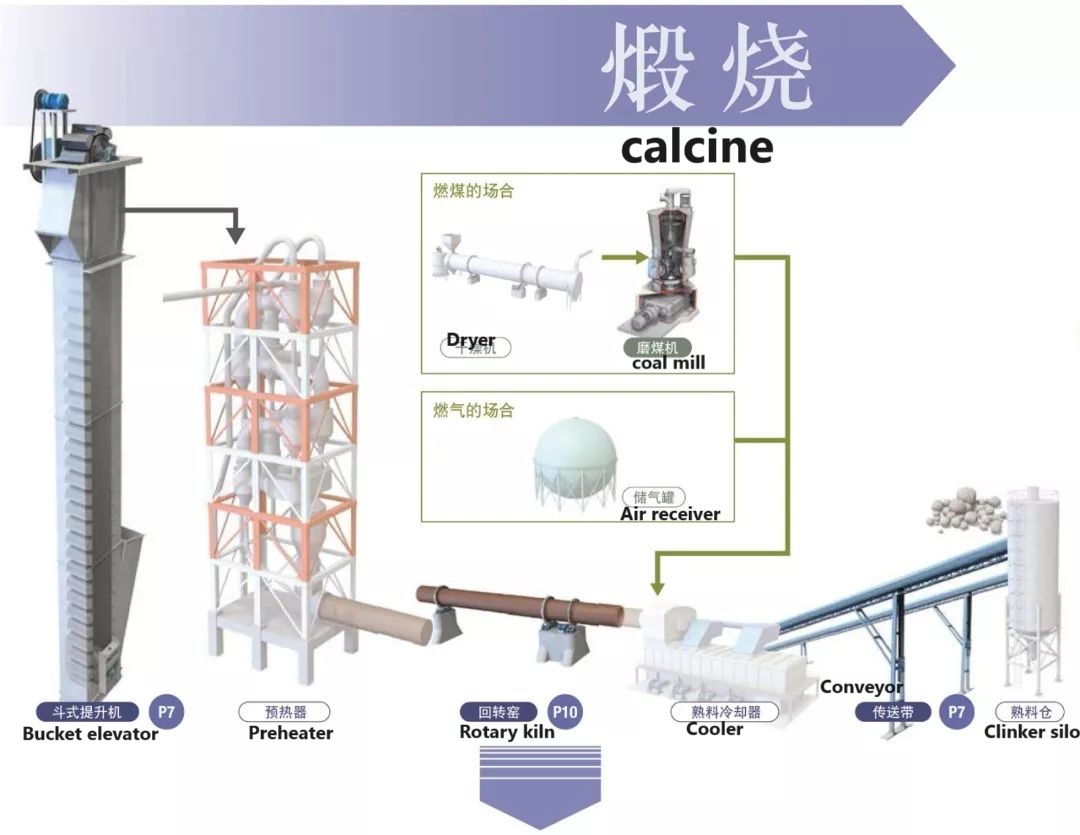

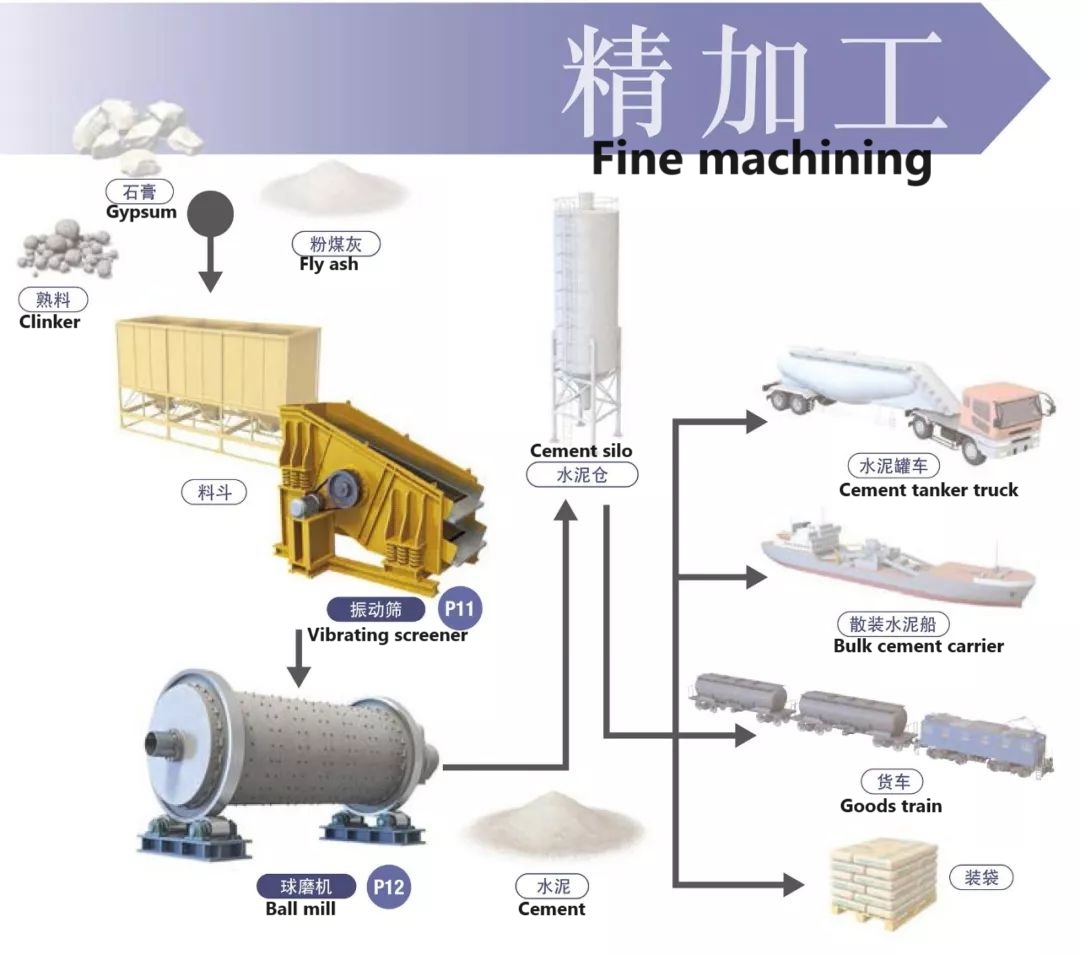

The cement industry is an important application field for large and medium-sized bearings. From material preparation, grinding, mixing, sintering to clinker grinding, every step of cement production requires bearings in the transmission and rotating parts of all mechanical equipment. Due to its high load-bearing capacity, high impact, and harsh environment, the requirements for bearings are also extremely strict. It is precisely because of the special usage conditions that, in order to ensure efficiency and consider cost-effectiveness, the cement industry uses more sliding bearings besides rolling bearings

| TYPE | DIMENSION(d*D*B) | WEIGHT (KG) |

| NU3288X2/HC | 400*540*60 | 34 |

| NNU41/600/HCCNHW33YA3 | 600*980*375 | 1101.5 |

| NU31/530/HCEC3 | 530*870*270 | 670 |

| NU12/500X3/HCP6 | 500*900*210 | 585 |

| NU2156X2M/C3YA4-1 | 75*130*25 | 1.24 |

| NU31/500 | 500*830*264 | 563 |

| NU2252MA | 260*480*130 | 106 |

| NU2292MA/HCC9 | 460*830*210 | 530 |

| NU2252X2M | 260*480*130 | 111 |

| NNU4092/W33 | 460*680*218 | 240 |

| NNU4180/HC | 400*650*250 | 324 |

| NNU6/575/HCC3 | 575*950*270 | 808 |

| 23272CA/HCC3 | 360*650*232 | 335 |

| NU3092M | 46*680*163 | 207 |

| NNU4196/HCW33YB2 | 480*790*308 | 602 |

| NU31/530/HCEC3 | 530*870*272 | 670 |

| 32234/HCC3DF | 170*310*182 | 619 |

| NNU4180/HC | 400*650*250 | 325 |

| 232/530CAK30/C3W33 | 530*980*355 | 1200 |

| 241/600CAK30/C3W33 | 600*980*375 | 1200 |

| 241/670CAK30/C3W33 | 670*1090*412 | 1600 |

| 232/750CAK30/C3W33 | 750*1360*475 | 3050 |

| 241/750CAK30F3/C3W33 | 750*1220*475 | 2100 |

| 232/800CAK30/C3W33 | 800*1420*488 | 3320 |

| 232/900CAK30F3/C3W33 | 900*1580*515 | 4360 |

| 241/1120K30F3/C3W33X | 1120*1750*630 | 5610 |

| 241/560CAK/W33 | 560*920*355 | 985 |

| 241/560K30/C3W33 | 560*920*355 | 985 |

| 232/600CAKF3/YA2W33 | 600*1090*388 | 1600 |

| 23296CAKF3/W33 | 480*870*310 | 800 |

| 232/600CAKF3/YA2W33 | 600*1090*388 | 1600 |

| 232/750CAK/C3W33 | 750*1360*475 | 3050 |

| 241/750CAK30/C3W33 | 750*1220*475 | 2100 |

| 24064CA/W33 | 320*480*160 | 100 |

| 24096CA/W33 | 480*700*218 | 285 |

| 23980CA/W33 | 400*540*106 | 71 |

| 29352 | 260*420*95 | 49 |

| 29252 | 260*360*60 | 18.5 |

| 29356 | 280*440*95 | 53 |

| 24068CA/W33 | 340*520*180 | 140 |

| 24064CA/W33 | 320*480*160 | 100 |

| 6080M | 400*600*90 | 87.9 |

| 230/500CAF3/W33 | 500*720*167 | 225 |

| 230/800CA/C4W33 | 800*1150*258 | 895 |

| 230/1000CAF3/C4W33 | 1000*1420*308 | 1600 |

| 248/1320CA/C4W33 | 1320*1600*280 | 1180 |

| 239/1060X2CAF3/W33 | 1060*1400*250 | 1080 |

| 249/1320CAF3/W33 | 1320*1720*400 | 2510 |

| 230/800CA/W33 | 800*1150*258 | 895 |

| 248/1320CA/W33 | 1320*1600*280 | 1180 |

| 230/530CA/W33X | 530*780*185 | 310 |

| 23256CA/W33 | 280*500*176 | 150 |

Bearings and faults in cement machinery equipment preventive and handling methods

(1) Choose bearings that match the required strength, and choose bearings produced by qualified large brand production enterprises to ensure reasonable design parameters and avoid design defects in the selected bearings that may affect the normal service life of the bearings.

(2) During the installation and replacement process of rolling bearings, it is necessary to strictly follow the installation operating procedures to ensure the balance of bearing installation, the correctness of force points, and the uniformity of force distribution. Firstly, it is important to align the position of the bearing and ensure that the inner surface of the bearing sleeve is struck during the installation process, and that all force points are balanced and pushed forward. Furthermore, the installation direction of the angular contact bearing should be consistent.

(3) The lubrication of bearings, whether it is rolling bearings or sliding bearings, is the most critical link for the normal operation and extended service life of bearings. During the installation and use of bearings, it is necessary to choose high-performance lubricants to continuously lubricate the bearings. It should be noted that due to the special nature of the cement production process, there are often hard foreign objects in the environment. When carrying out lubrication operations, the surrounding environment must be cleaned up to prevent the inclusion of hard foreign objects in the lubricant into the bearings, which may cause abnormal wear hazards to the operation of the bearings.

(4) The bearings in the mechanical equipment of the cement plant are more severely corroded than those in other environments. This requires us to pay attention to reducing bearing corrosion as much as possible during the maintenance process of bearings, placing them in a closed environment as much as possible to prevent the inflow of materials during the production process. After discovering corroded bearings, the liquid in the bearings should be immediately drained to increase the sealing of the bearings.

(5) Bearings are vulnerable parts in mechanical equipment and have their corresponding service life. Records should be kept during the installation of bearings. When the bearing reaches its predetermined service life, intensive testing should be carried out to prepare for replacement. In daily use, a comprehensive monitoring system should be established to timely identify safety hazards in bearings through detailed data such as bearing temperature, color, and depth of friction grooves, and eliminate them in the primary stage.

Application

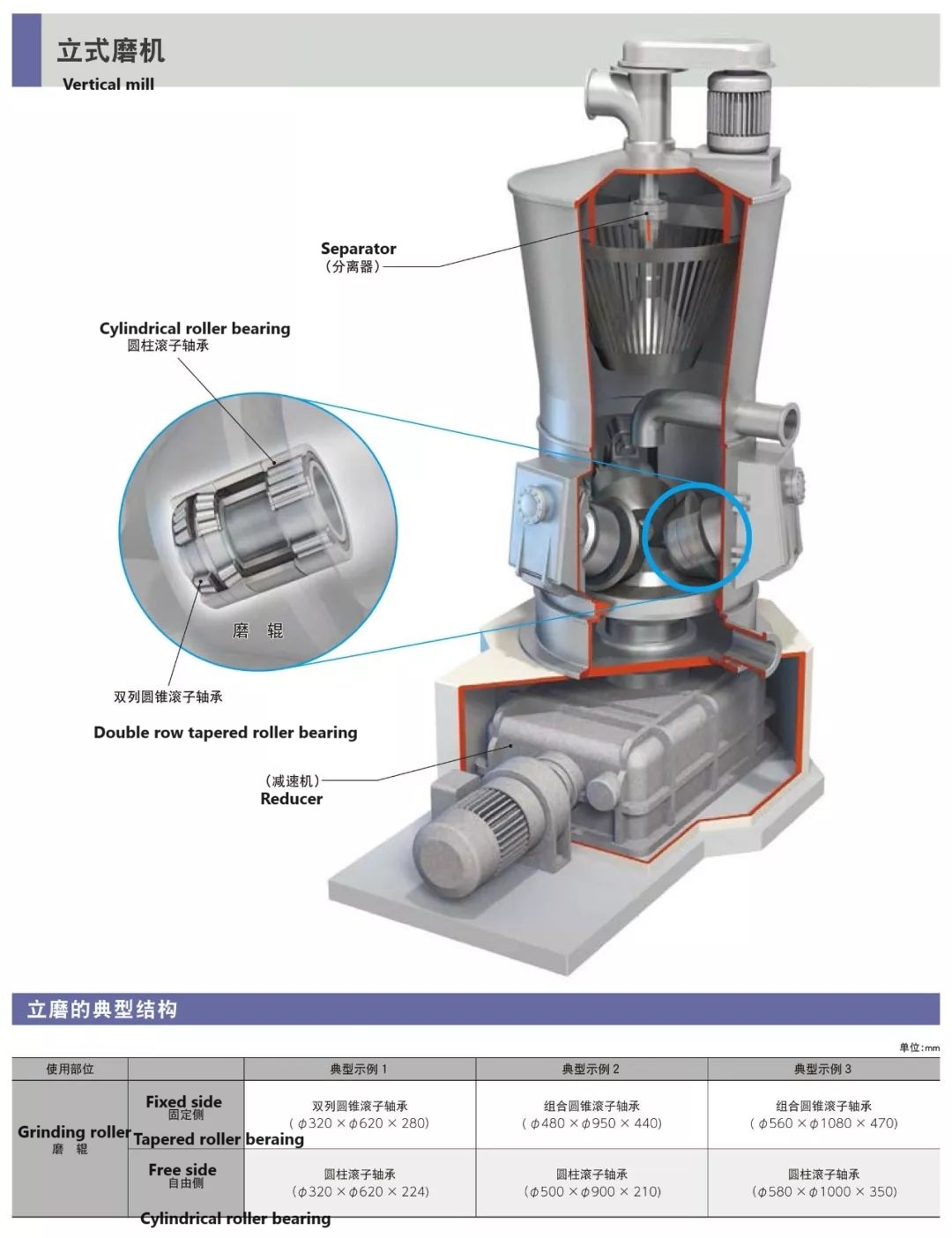

vertical mill bearing

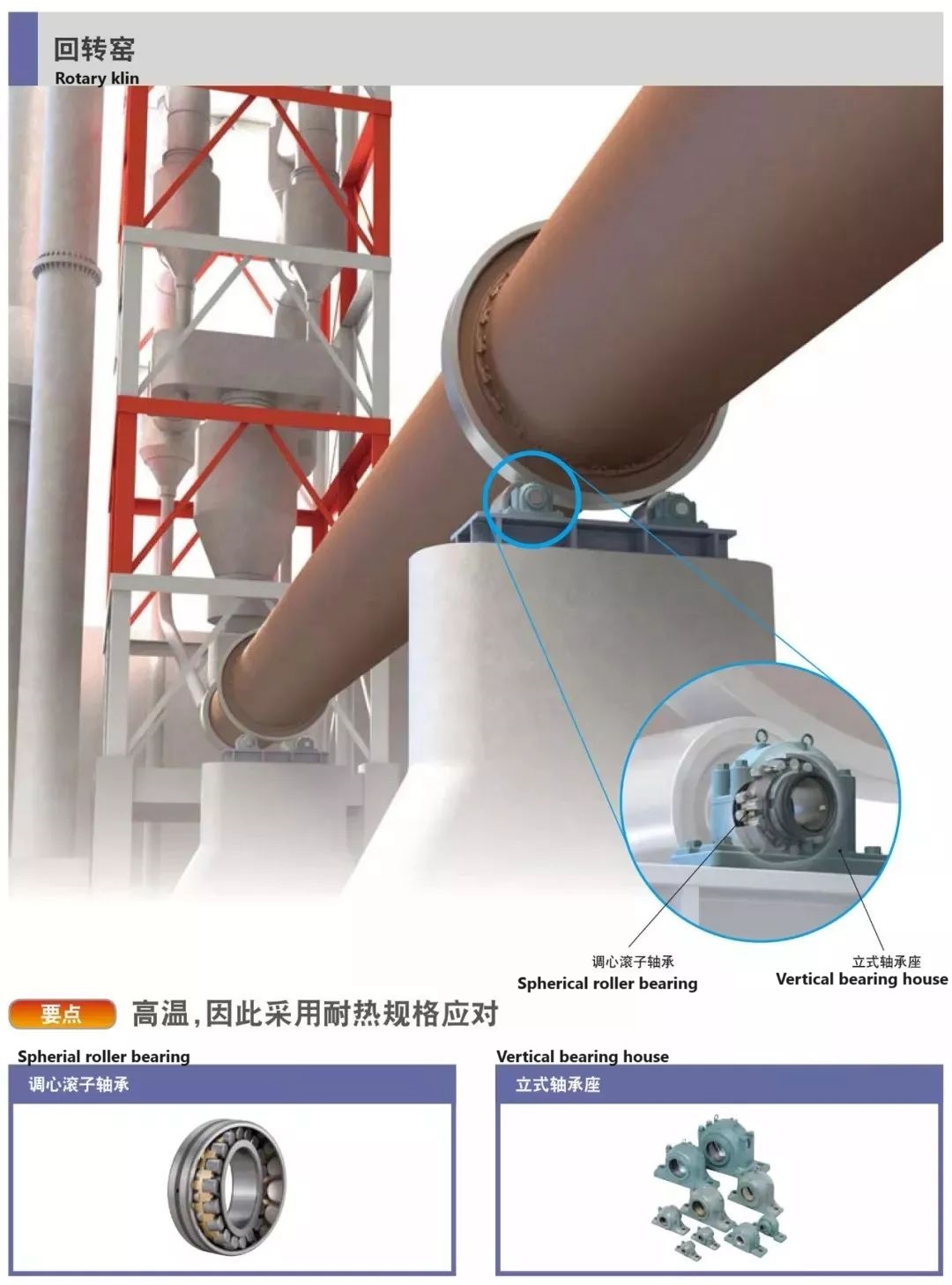

Rotary Kiln bearing

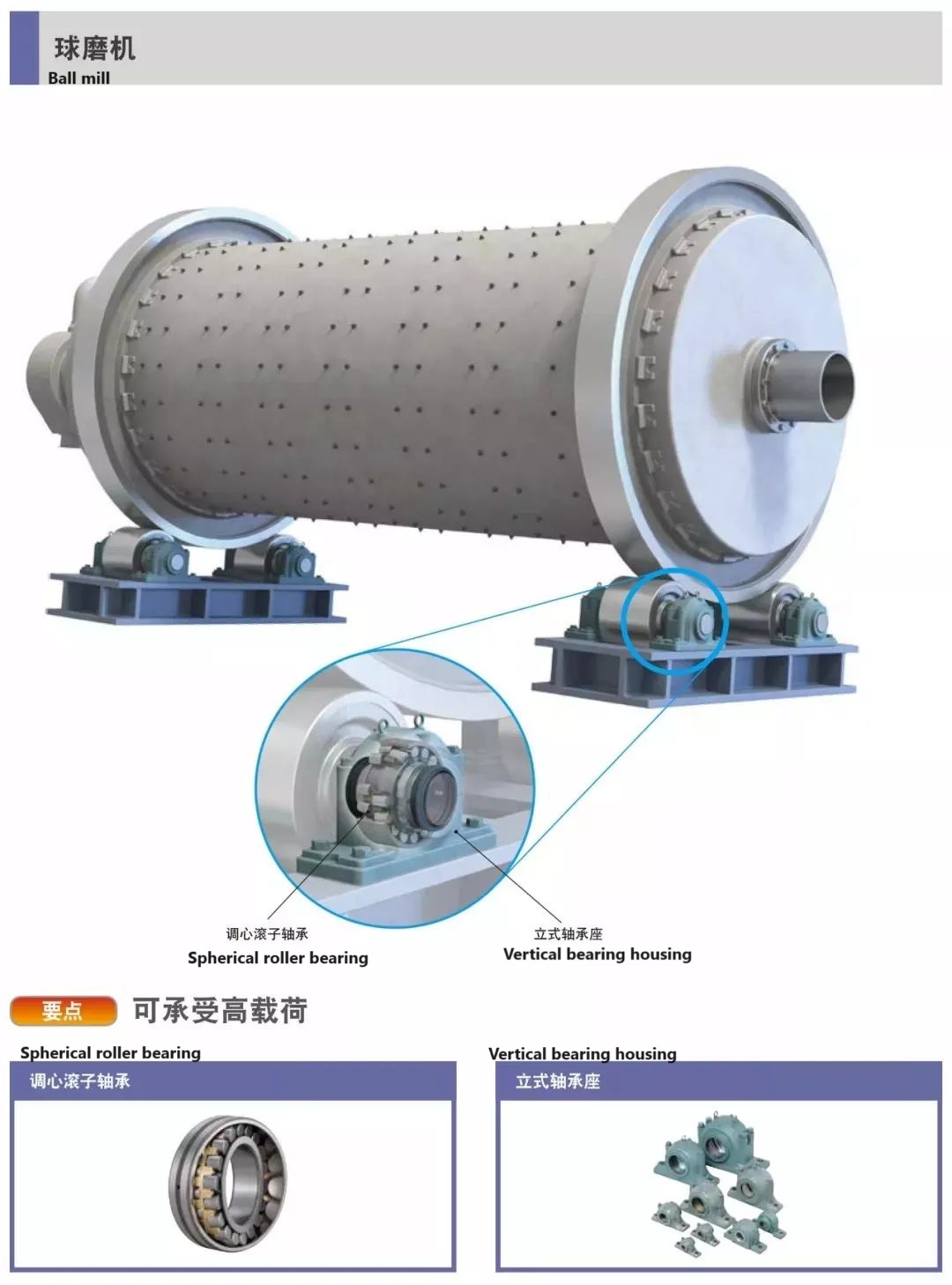

Ball mill bearing

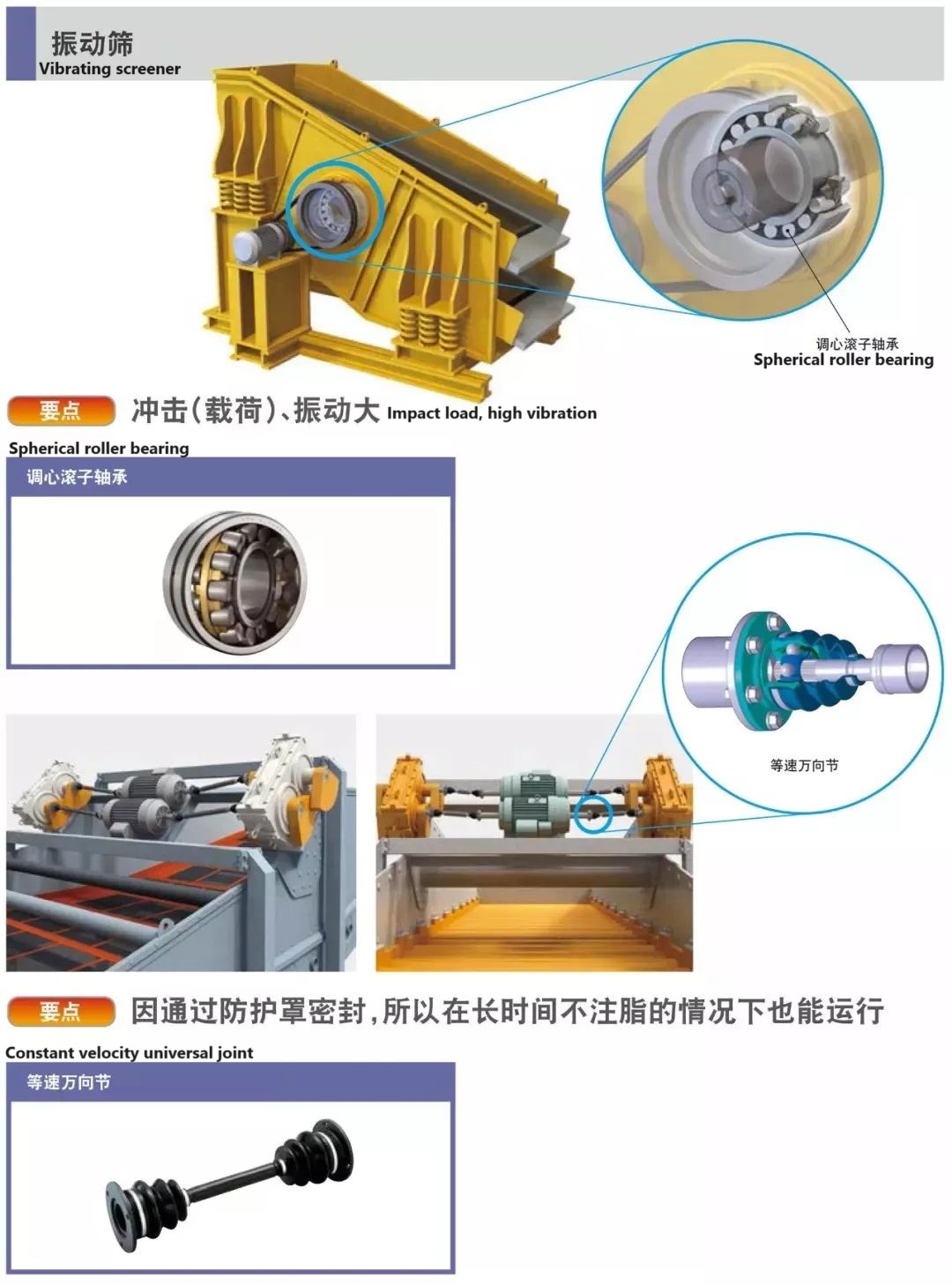

Vibrating screener bearing

Crusher bearing

Impact crusher bearing

jaw crusher bearing

cone crusher bearing

Name: Ms Linda Ren

Tel:0086 15366795302

Whatsapp:008615366795302

Email:info@dpmachinery.com

Add:A11-423, China Safety Valley, Lijiang Road South, Xuzhou High-Tech Industrial Development Zone, Jiangsu, China--221000