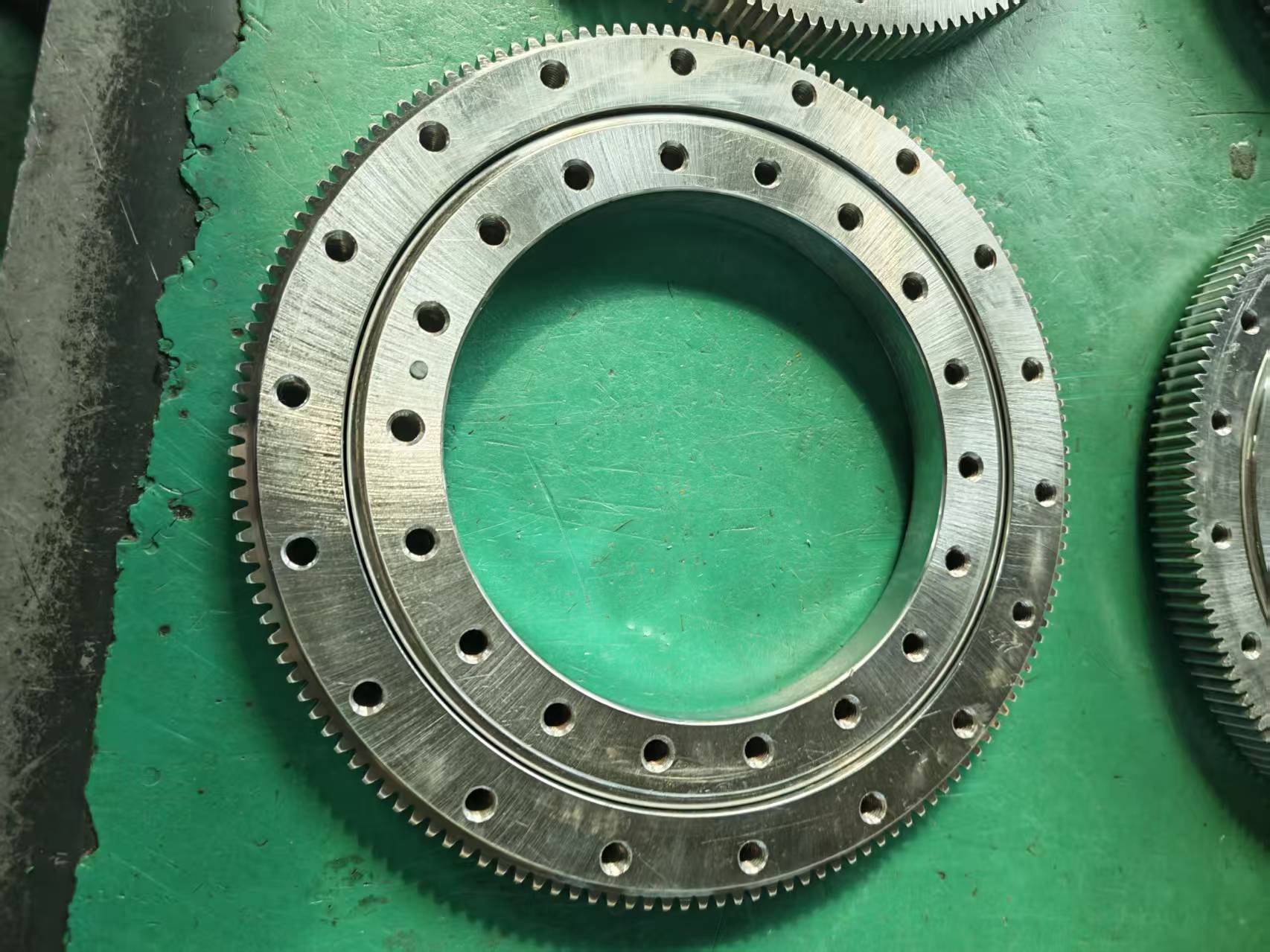

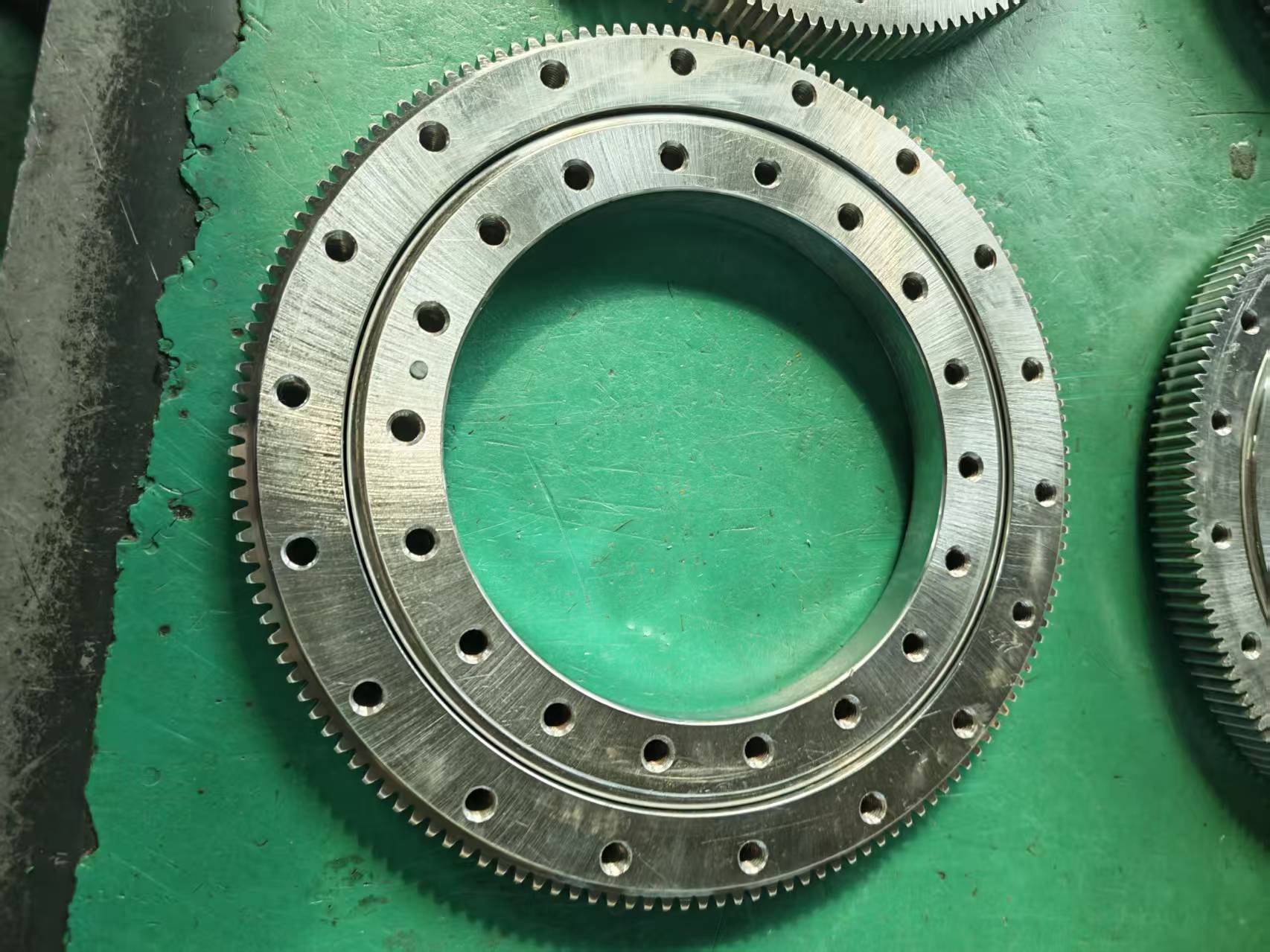

Causes of Operation Jamming and Optimization Methods for Precision Crossed Roller Slewing Bearings

Precision crossed roller slewing bearings, specialized for use in robot arm joints and rotating parts, significantly impact key performance indicators such as operational smoothness, repeat positioning accuracy, motion precision, and operational reliability. The pre-delivery inspection of these bearings is particularly critical.

Reasons for Sticking

1.If the plug is pressed too deeply or insufficiently during assembly, it will not only affect the subsequent alignment of the taper pin but also cause depressions or protrusions in the raceway at the plug location. This results in friction between the rollers and the plug during operation, ultimately leading to sticking.

2.If the plug rotates during assembly, discontinuities will occur in the outer ring raceway at the corresponding position. This causes the rollers to become scratched at the plug location, eventually resulting in operational sticking.

Assembly Optimization Methods

Reasonable control of the protrusion, depression, and inclination angle of the plug during assembly can ensure the plug’s assembly accuracy, thereby reducing the probability of jamming in crossed roller slewing bearings.

The assembly accuracy of the plug has a significant impact on the raceway roundness. A negative fit clearance between the plug and the plug hole increases assembly difficulty, making the plug prone to rotation and inclination, which results in a large starting friction torque of the bearing. In contrast, a positive fit clearance leads to a smaller starting friction torque compared to a negative one.