ISO 15243 Bearing Failure Modes During Operation - Part 1

ISO 15243:2017 classifies the failure modes of bearings installed in equipment during operation, excluding manufacturing defects such as partial imperfections. The standard categorizes failure modes into six major classes: rolling contact fatigue, wear, corrosion, electrical pitting, plastic deformation, and cracking & fracture.

Descriptions of the six failure modes are as follows:

1. Rolling Contact Fatigue (ISO 5.1)

Subsurface-initiated fatigue (ISO 5.1.2): Caused by cyclic loading on the rolling contact surfaces, leading to gradual material structure changes and subsequent microcrack formation over time. Microcracks typically originate at inclusions in the bearing steel beneath the surface, then propagate to the surface resulting in spalling. This type of fatigue is influenced by bearing quality, applied load, lubrication, and cleanliness. Subsurface fatigue may accelerate if the bearing is subjected to high stress due to transient overload or other operating conditions that impair material performance. In such cases, fatigue life is significantly shortened.

Surface-initiated fatigue (ISO 5.1.3): Fatigue originating at the rolling surface, usually caused by surface damage due to inadequate lubrication or contamination. Insufficient lubricating film thickness and excessive rolling of solid contaminants lead to metal-to-metal contact, resulting in mutual shearing of surface asperities. This is followed by sequential microcracking, microspalling, and ultimately surface-initiated fatigue.

2. Wear (ISO 5.2)

Abrasive wear (ISO 5.2.2): Gradual loss of surface material due to the action of abrasive particles such as contaminant particles. It can also occur when lubrication is inadequate. A typical characteristic is a dulled surface appearance. Abrasive wear is a degenerative process that ultimately damages the microgeometry of the bearing's rolling surfaces. Abrasive particles can rapidly wear the raceways of the inner and outer rings, rolling elements, and cage pockets. This type of wear may be caused by contaminant intrusion into the lubricant and bearing, or insufficient lubricant in the rolling contact.

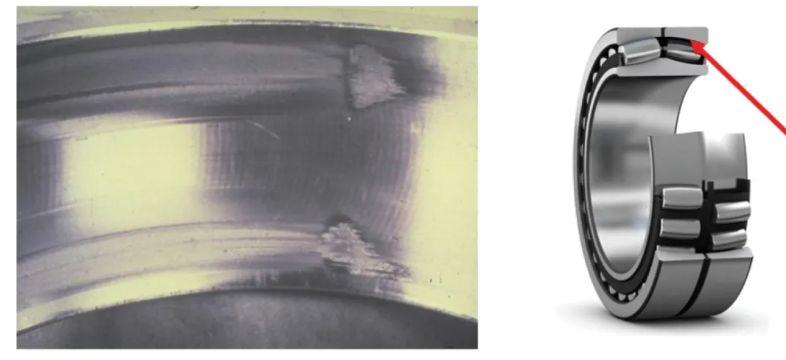

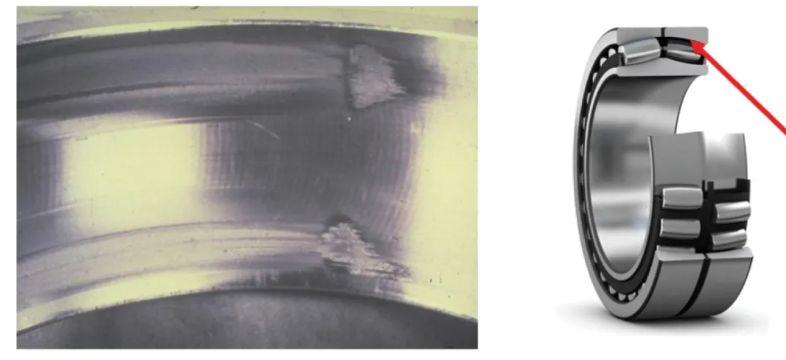

Adhesive wear (ISO 5.2.3): A phenomenon where material transfers from one surface to another when two components within the bearing slide against each other, accompanied by frictional heating. This may result in material tempering or secondary hardening. Adhesive wear occurs when the bearing is underlightly loaded and the rolling elements of radial bearings experience severe acceleration when entering the loaded zone, manifesting as smearing (scuffing, galling). Angular contact ball bearings may also suffer adhesive wear under operating conditions of high speed, light load, and excessive internal clearance.